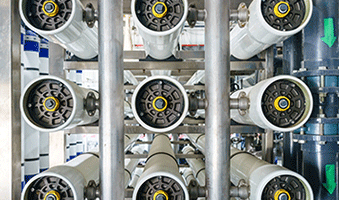

REVERSE OSMOSIS

Reverse Osmosis / RO is a technology used to remove dissolved solids and impurities from water using a semi-permeable RO membrane which allows the passage of water but leaves the majority of dissolved solids and other contaminants

behind. The RO membranes require water to be under high pressure (greater than osmotic pressure) to do this. The water that passes through the RO membrane is referred to as the "permeate" and the dissolved salts that are rejected

by the RO membrane is referred to as the "concentrate". A properly run RO system can remove up to 99.5% of incoming dissolved salts and impurities.

The growth of membrane technologies in many diverse applications has been remarkable. Reverse Osmosis has been extremely effective in boiler feedwater preparation and improving boiler operation. Membrane technology applications are continuing to develop for the treatment of wastewater and municipal water treatment systems.